“All you need to know about stamped concrete. We will discuss the key benefits that come with stamped concrete. We have chosen five of the most common reasons that make you consider installing stamped concrete.

What is stamped concrete?

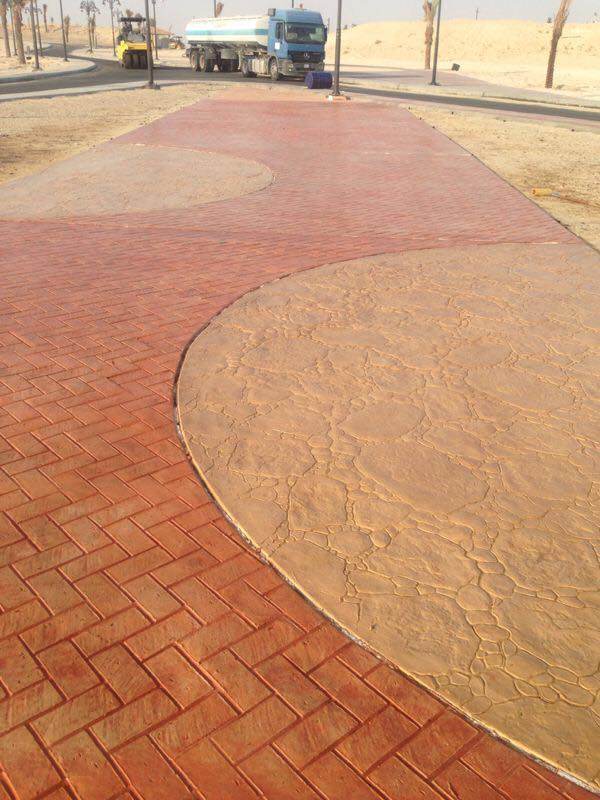

Simply put, stamped concrete (also known as imprinted or sealed concrete) involves pouring concrete on a sub-base, followed by applying color and then stamping. This is unlike traditional concrete pouring, which usually involves using forms to create your finish.

Once the concrete becomes wet, this is when the pattern is applied. You can choose from a variety of imprints, with the most common being brickwork, cobblestone, and ashlar stone. Stamped concrete is a popular choice for residential properties, especially for paved walkways, as it adds attractiveness to your property.

High-Quality Printing

The most important thing to consider is the quality of stamped concrete. Fresh concrete requires extreme care, dedication, and patience to set it correctly, and anything less will result in an inconsistent appearance, leaving you with an unfinished and structurally poor concrete floor.

In most cases, a contractor may use 6-8 rigid stamp mats and one flexible mat in a set. Around six mats are needed to cover the narrower part of a driveway, while the flexible mats, as you might guess, are used for areas that do not suit rigid mats and imprinting. Most stamp mats come in a size of 600 mm × 600 mm, but there is flexibility in extinguished size; you just need to know the size you want for the mats and then search for the best prices.

Color Coordination

Color coordination is something you’ll need to consider when installing stamped concrete to ensure the floor achieves the color you’re looking for. The main components of stamped concrete include colored surface hardener and antiquing release agents.

If the colored surface hardener is not used correctly or there is not enough of it, it will result in a poor final appearance. This is particularly noticeable in larger commercial jobs, such as the floors of retail stores.

For larger commercial jobs, it will take several concrete deliveries, leading to slight color variations in each concrete mix. The surface hardener’s job is to match the colors together when applied. This is ideal for large jobs that take more than a few days to complete.

For every square meter of stamped concrete, you’ll need approximately 2.5 kg of colored surface hardener. When applying it to heavily trafficked areas, such as driveways, parking lots, and steps, we recommend applying more hardener to withstand the extra traffic movement.

Note: If you’re buying pre-colored concrete, you cannot strengthen it further with a hardener as it will affect its appearance. Additionally, ensure the concrete is mixed correctly if you’re buying it pre-colored; otherwise, it will lead to poor quality and an unfinished appearance.

Also, be aware that before washing the release agent, the floor will appear darker than the chosen color. This is normal and can be rectified when washing the release agent.

It’s crucial to remove all old release agents, or else it won’t adhere to the concrete. Again, this may lead to an unfinished appearance, but it can be rectified by removing the release inhibiting material and repeating the cleaning/sealing process.

Ensuring Long-Term Durability

The materials used for the compacted sub-base combined with the bottom layer (the ground beneath the base, which can be soil or stone, etc.) are necessary to ensure the durability of the stamped concrete floor above. Additionally, the applied concrete mix also plays a significant role in ensuring strong structural integrity for years to come.

This is especially important in heavily trafficked areas, such as driveways, multi-level parking lots, and warehouses that operate machines daily.

Reducing the Chance of Concrete Cracking

If you are using stamped concrete for walkways, make sure there is a minimum of 300 kg of cement per cubic meter when applying. In cold weather, you’ll need 350-380 kg as an estimate.

You can also choose to add an air-entraining admixture to help enhance the floor’s durability and resistance to cracking resulting from heavy traffic and weather.

Note: The concrete mix must be the right mix. When the concrete is mixed professionally, it significantly reduces the likelihood of cracking. This is crucial for walkways and parking lots; its thickness should not be less than 100 mm to bear the weight of vehicles. For local paved areas, the thickness of the concrete should range from 150 to 175 mm.

Concrete should be thicker in high-traffic areas or where control joints cannot be cut for any reason; 150 mm for local paved areas.

Use a Membrane Slab When Needed

There is some controversy about when and whether membrane slabs should be used. Some companies may use a membrane slab to allow the concrete to move independently, reducing stress buildup and essentially minimizing the likelihood of golf ball sets selling for concrete cracking. On the other hand, others may choose not to use it because they prefer the concrete to naturally seep into the stone.

The decision to use or not use a membrane slab is up to the concrete contractor; it is not mandatory.

Placing Expansion Joints Correctly

Expansion joints and movement points are another factor that stirs controversy, this time between the contractor and the client. As the name suggests, expansion and movement joints are placed in areas where the concrete is supposed to crack, or alternatively, they are placed so that the concrete cracks at this point to ensure it does not crack in a more difficult location.

Usually, these joints are cut in high-stress areas, such as the external corners of buildings. The maximum size of the slab within the paved area should also be defined at 20 square meters, with a maximum length-to-weight ratio of 2:1.

Timing the Cutting of Expansion Joints

It is strongly advised to cut expansion joints sooner rather than later to ensure that cracks do not appear before it’s too late. Cutting joints is relatively easy; it should be done on the same day of pouring and needs to be cut to about a quarter of the depth of the concrete. Later on, you’ll need to use a diamond saw cut to about half the depth of the concrete. Do not cut the concrete slab immediately.

Minimizing Maintenance and Maximizing Results

Using an acrylic-based water repellent on stamped concrete (only once dry) will improve its overall appearance. Acrylic water repellent is more problematic, so steer clear of it regarding stamped concrete. Additionally, the repellent material should be applied every four years or so to maintain the appearance of stamped concrete. This is not mandatory, but it will keep your walkway (or wherever stamped concrete is installed) looking great for years to come.

Filling Expansion Joint Gaps

Fortunately, stamped concrete requires minimal maintenance once installed (aside from cleaning to maintain appearances). Although it may still require resealing every two years, this is not a labor-intensive job, and in the long run, it will save you money as it reduces the likelihood of damage or deformation.

Additionally, to mitigate the threat of weeds and infiltration, it’s important to use a silicon sealant to fill expansion joint gaps. Silicone sealants come in several colors, so look for the one that best suits the stamped concrete (silicone enhances the appearance of concrete).”

We Specialize in

DECORATIVE CONCRETE

DECORATIVE CONCRETE

- STAMPED CONCRETE

- RESIN BOUND AGGREGATE

- EXPOSED CONCRETE WORKS

- PLASTER PRINTED FINISH

- COLORED CONCRETE FLOORS

- BROOM FINISH CONCRETE

Civil works

Civil works

Jabal Civil Work encompasses expert services in infrastructure and structural development, emphasizing precision and durability.

Equipment Rental

Equipment Rental

Jabal Construction specializes in a wide range of construction projects, prioritizing quality, safety, and client satisfaction.

We are ready to execute all stamped concrete works throughout the Kingdom of Saudi Arabia.

Efficiency in completion and the capability to undertake large projects are our strengths.

Eng. Adnan: 0504400267 | Eng. Mohammad Tawalbah 0501244102 | Eng. Abdullah 0554180476